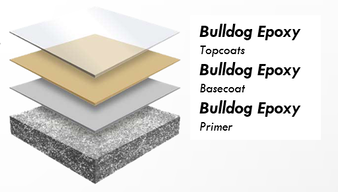

Bulldog Color Base Coat Instructions

|

Solid Color Epoxy Flooring is great for the strength and durability of any concrete surface with an epoxy flooring system. Our Soild Epoxy Base is a durable floor coatings that can be used in a multitude of commercial and residential applications; showrooms, warehouses, kitchens, airplane hangars, and garages. Epoxy floor systems are a cost effective way to strengthen concrete and are available in a variety of solid colors.

APPLICATION INSTRUCTIONS: Bulldog Epoxy recommends consulting your floor coating system manufacturer regarding specific instructions, coating recommendations, and application methods. These application instructions are designed to be general guidelines that will vary depending on the specific coatings you choose. STEP 1: Base Colors Preparation In order to avoid unwanted streaking or comet trail effects, Base Colors should be pre-mixed into the resin component of your coating system 24 hours prior to application, using proper mixing procedures to avoid adding air into the coating while mixing. After mixing is complete, let the mixture rest for at least 24 hours to allow the Base Colors to properly disperse in the resin. STEP 2: Surface Preparation As with all high-performance floor coating systems, recommends mechanical surface preparation for optimal coating adhesion. In most cases, proper surface profiling can be achieved using a diamond grinder or shot-blaster. STEP 3: Base Colors Coat After the primer/basecoat is fully cured, the coating can be applied. The recommended application rate is 75-100 square feet per gallon. This thickness will ensure the Base Colors evenly coat the desired surface. Once the epoxy is applied, the Base Colors begin to shift and create the desired pearlescent patina effect. STEP 4: Clear Topcoat For enhanced durability, smooth texture, and a semi-gloss or matte finish, the dried Metallic Color coating surface can be lightly screened or sanded, and a clear topcoat may be applied. |

ESI Epoxy Solid Base Colors

|